1995 to present

Specializing in the production of motor grade deep groove ball bearings

Zhejiang Xin Dong Huang Bearing Co., Ltd. is a professional manufacturer of motor grade deep groove ball bearings, the company is committed to the development of internal diameter 2mm-100mm of all kinds of precision deep groove ball bearings. The pursuit of excellence, forever brilliant. Advanced technology, sophisticated equipment, complete testing and testing methods, as well as high-quality technical development team and capable and skilled staff, carefully built "VCD", "MOS" two brands of bearings. The rise of VCD bearings for the professional production of high-grade deep groove ball silent bearings opened a brilliant page.

Xin Dong Huang Product Series

Committed to the development of various types of precision deep groove ball bearings with an inner diameter of 2mm-100mm

Application areas

VCD brand bearings are widely used in the field of micro motors, household appliances, fitness sports equipment, automobile and motorcycle parts, electric tools, instruments and automation equipment and other transmission devices.

Zhejiang Xin Dong Huang Bearing Co., Ltd. is a professional manufacturer of motor grade deep groove ball bearings, the company is committed to the development of internal diameter 2mm-100mm of all kinds of precision deep groove ball bearings. The pursuit of excellence, forever brilliant. Advanced technology, sophisticated equipment, complete testing and testing methods, as well as high-quality technical development team and capable and skilled staff, carefully built "VCD", "MOS" two brands of bearings. The rise of VCD bearings for the professional production of high-grade deep groove ball silent bearings opened a brilliant page.

Research & Development

The lifespan and durability of bearings

VCD has its own professional bearing life testing machine for testing the service life of bearings. We place the bearings into (ABLT-3). Set a radial load of 1KN and an axial load of 500N, and run continuously at a speed of 15,000 revolutions per minute for 1,000 hours, then disassemble the bearings for analysis. Through experiments, VCD bearings have the advantages of long service life and high durability.

High and low temperature resistant bearings

Nitrile rubber NBR (-40~250F) 40~90 low compression characteristics, high extensibility, high wear resistance, excellent oil resistance is not suitable for high temperature conditions, and avoid direct sunlight and the erosion of chemicals (such as acetic ether esters, etc.).

High-speed bearing

When the bearing operates under load, heat is generated internally due to rotation, sliding, and friction. As the operating speed of the bearing increases, the temperature also rises. If the speed is too high and the temperature exceeds a certain limit, the effectiveness of the lubricant will be significantly reduced, and the bearing will not be able to operate stably.

Silent bearing

In recent years, VCD has been committed to reducing friction, making the challenge of mechanical operation more efficient. Through optimized design, lubrication, retainers, and manufacturing technology, our deep groove ball bearings currently have significantly reduced friction torque or friction loss in certain bearing sizes and application conditions, with some even reducing by 30% compared to traditional bearings.

Dustproof and waterproof bearings

The sealing performance is crucial for the cleanliness of lubricating grease and the overall service life of bearing applications. The integrity of bearing sealing performance must be able to block contamination and ensure that the lubricating grease does not leak.

Information & Dynamics

The Mid-Autumn Festival and National Day are approaching. Here, I would like to extend holiday greetings to all employees working hard in various positions at the company! According to the holiday arrangement issued by the General Office of the State Council for 2024, and in consideration of the actual situation of the company, the leadership has decided on the specific holiday arrangements for the Mid-Autumn Festival in 2024 as follows:

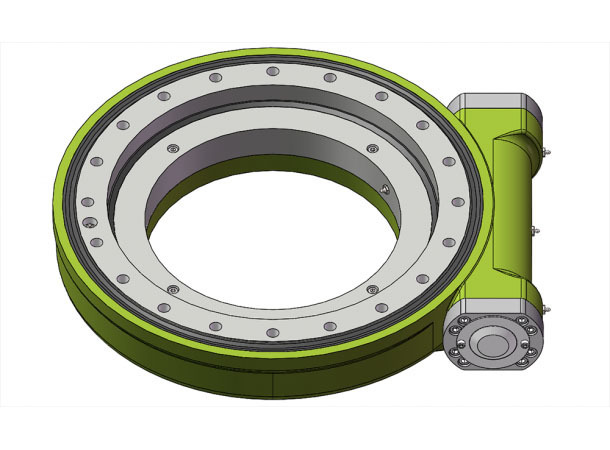

The worm gear reducer is a two-stage reduction transmission mechanism, with the first stage being belt transmission and the second stage being Archimedes cylindrical worm gear transmission. Its characteristics include: compact structure, large transmission ratio, stable and reliable operation, noiseless, and the reducer also has self-locking properties under conditions of a small lead angle of the worm.

On the afternoon of August 5, 2020, the signing ceremony for the school-enterprise cooperation in production, learning, and research between Zhejiang University of Technology Zhijiang College and the People's Government of Henghe Town, Cixi City, as well as between Ningbo University School of Science and Technology and the Cixi City Bearing Industry Association, was grandly held at No. 446, South Third Ring Road, Henghe Town, Cixi City.